Note: The details cannot be disclosed here due to confidentiality concerns

This project is conducted by studying various offset techniques such as trimming, auto-zeroing, and chopping through TMC papers and data, and improved the temperature distribution of BGR designed on REF Block in the first week of the internship through chopper design.

The offset cancellation technique includes trimming, auto-zeroing, and chopping. Trimming is a form of measurement and an offset ‘during’ production, and the following two latter methods are ‘dynamic’ offset techniques. Each technique has its strengths and weaknesses. Right off the bat, trimming is a form of measure and offset cancellation during production, and it is difficult to offset micro-voltage(uV) level initial offset due to offset drift. In other words, it is a technique that can cancel a bulky offset. Therefore, dynamic offset cancellation became necessary.

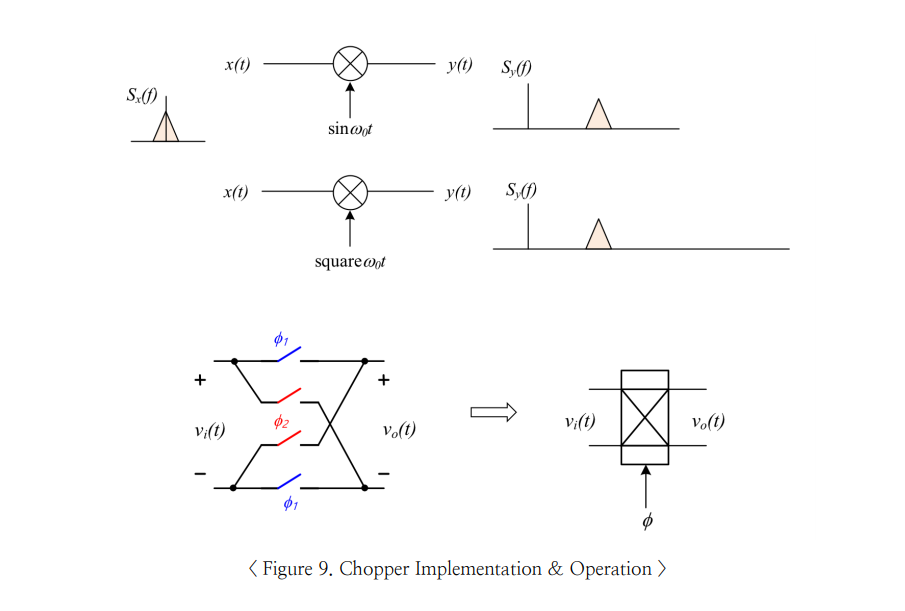

Subsequently, we will discuss Auto-zeroing. This technique is similar to discrete-time sampling. However, as shown in the below figure, if we sample the offset voltage in phase 1 to the capacitance and reversely apply in phase 2, the output of the amplifier is canceled. Through this, both offset and flicker noise can be reduced. The last offset canceling technique is the chopping technique using a chopper used in this project. Chopping is similar to continuous-time sampling. To briefly explain the Chopper principle, we can conceive of it as a technique to split the signal and noise band through frequency modulation.

A chopper is a device that forms square waves for the frequency conversion, and as shown in Figure 9, it is possible to form square waves by applying +vi in phase 1 and -vi in phase 2. Since it shows excellent performance in terms of power efficiency compared to auto-zeroing, the BGR offset distribution was reduced using chopping in this project.

The TMC BGR’s error sources are consisted of the following components; VBE dispersion, Current Source Mismatch, and Offset Voltage. The first two of which can be removed by trimming and Dynamic Element Matching (DEM), respectively, and Offset can be removed by chopper.

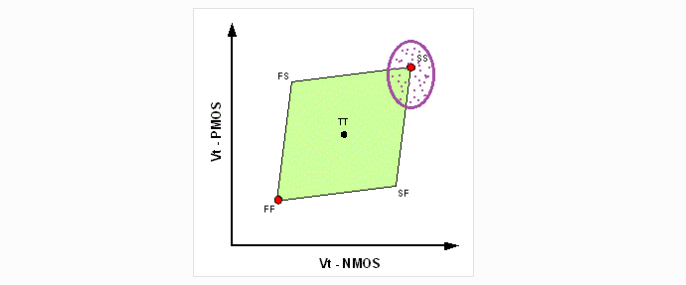

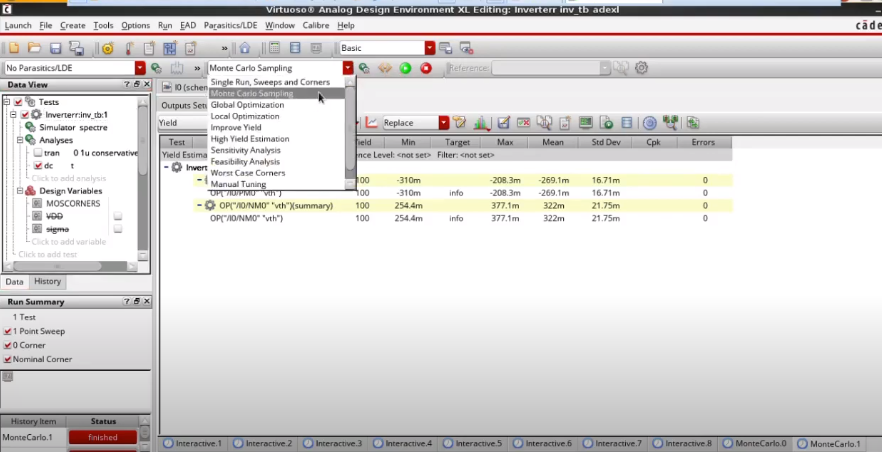

Chopper was added to the input and output of the Error Amp of the BGR circuit designed by the reference block, respectively, to proceed with the design. After that, Monte Carlo Simulation confirmed about 5% of Disruption Reduction in process corner. The detailed contents cannot be mentioned here due to confidential information issues.

[References]

- https://www.youtube.com/watch?v=ZnHk7JPX7Fc

- https://www.vlsifacts.com/mystery-monte-carlo-simulation/